RUBBER LININGS PULLEY LAGGING MANUFACTURING OF HAND BUILT HOSES RUBBER WEAR PADS IDLE SYSTEMS CONVEYOR BELTS

Features

ALROMAX offers a complete range of steel, impact, and HDPE idlers as well as frames for both standard usage applications and underground structures.

All idlers are manufactured to SABS SANS-1313 specifications. Established manufacturing principles ensure the customer is supplied with the highest quality product with the benefits they seek.

ALROMAX Idlers not only supplies the market with the full range of SABS industry-standard idlers and frames but also has the capability and facility to manufacture the right product to fit the customer’s needs.

Benefits

ALROMAX Idlers are manufactured to SANS-1313-1:2012 and SANS-1313-3:2012 Specifications.

- Low seal friction

- Manufactured to controlled SABS Specifications.

- Quality and concentricity within SANS Specified Tolerances

- The highest quality product with additional benefits

- Capability to customise products to suit the customer requirements

- All tubing and shafting cut from SABS certified stock to exact size and customer end product requirements

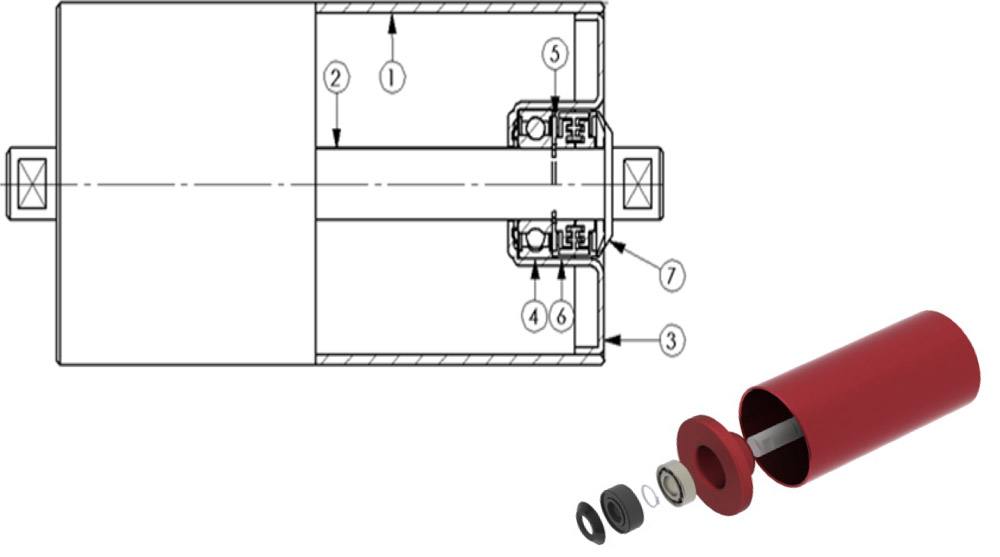

Steel Idler

1. Steel Tube

- ø127 x 3.8 mm THK nominal diameter

- ø152.4 x 4 mm THK nominal diameter

- Steel tube grade SAE1008 manufactured to SANS 657/3.

2. Steel Shaft

- ø25 and ø30 bright mild steel solid shafting, drawn to limits specified for accurate radial clearance of inner

bearing race. - Steel shafting grade 070M20 EN3A BS 970 part 1

3. Bearing Housing

- 2.5 mm THK die stamped steel housing specifically designed to guarantee minimum T.I.R of idler on final assembly. 4 mm THK steel housing used with Series 30 Idlers.

4. Ball Bearing

- ø25 6205 2RS C3 deep groove ball bearing (Dynamic load rating of 14900 N and a static load rating of 7800)

- ø30 6306 2RS C3 deep groove ball bearing (Dynamic load rating of 28100 N and a static load rating of 14600)

- Sealed and factory greased for life. Lubricant used LGMT 2.

5. Steel Circlip

- Circlip positioned axially to provide 0.7 mm end play maximum. To SABS SANS1313-1 specifications.

6. Labyrinth Seal

- ø25 5-part nylon labyrinth seal; providing ±65 mm of travel to drastically lower dust and moisture ingress into the idler. Factory greased for life. 3-part labyrinth seal for Series 30.

7. Flinger Ring/Dust Cover

- Polyethylene dust cover to limit dust and dirt contact between the outside environment and the labyrinth

seal.

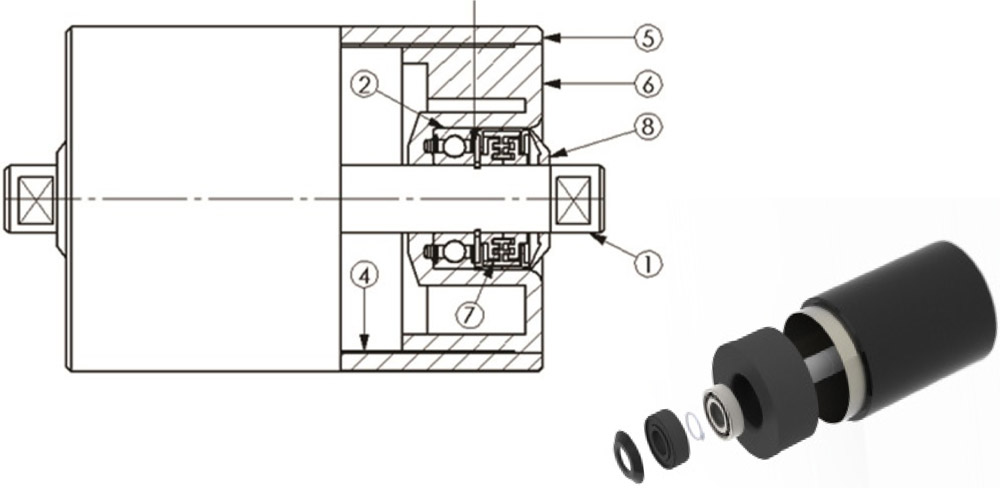

Hdpe Idler

1. Steel Shaft

- ø25 bright mild steel solid shafting, drawn to limits specified for accurate radial clearance of inner bearing race, Steel shafting grade 070M20 EN3A BS 970 part 1.

2. Ball Bearing

- 6205 2RS C3 deep groove ball bearing

- Bearings to have a dynamic load rating of 14,900 Newtons and a static load rating of 7,800 Newtons.

- Sealed and factory greased for life. Lubricant used LGMT 2.

3. Steel Circlip

- Circlip positioned axially to provide 0.7mm end play maximum. To SABS SANS1313 specifications.

4. Inner Steel Core Tube

- ø114.3 x 2 mm THK electrically welded structural tube, Steel tube grade S355 SANS 657/1

5. Outer HDPE Sleeve

- 6.5 mm THK HDPE (High-density Polyethylene) sleeve offer superior abrasion resistance, corrosion resistance, and lower material build-up compared to steel tube idlers.

- HDPE 100 material grade SDR17 PN10 4427/2 P/E. Manufactured to SANS4427-2 specification.

6. Bearing Housing

- Bearing housing is manufactured from 50% impact modified nylon and 50% Nylon 66 fibre. Internally ribbed for added rigidity.

7. Labyrinth Seal

- ø25 5-part nylon labyrinth seal; providing ±65 mm of travel to drastically lower dust and moisture ingress into the idler. Factory greased for life.

8. Flinger Ring/Dust Cover

- Polyethylene dust cover to limit dust and dirt contact between the outside environment and the labyrinth seal. An additional double-lip seal can be installed in high-moisture environments.

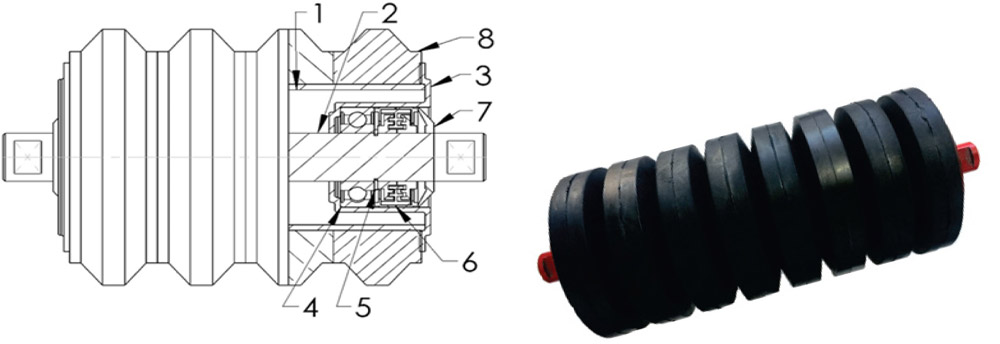

Impact Idler

1. Inner Steel Core Tube

- 76.3 x 3 mm THK electrically welded structural tube for S25 idlers.

- 88.9 x 4 mm THK electrically welded structural tube for S30 idlers

- Steel tube grade S355 SANS 657/1

2. Steel Shaft

- ø25 or ø30 bright mild steel solid shafting, drawn to limits specified for accurate radial clearance of inner bearing race.

- Steel shafting grade 070M20 EN3A BS 970 part 1

3. Bearing Housing

- 2.5 mm THK die stamped steel housing specifically designed to guarantee minimum T.I.R of idler on final assembly. 4mm THK for Series 30 impact idlers.

4. Ball Bearing

- ø25 6205 2RS C3 deep groove ball bearing (Dynamic load rating of 14900 N and a static load rating of 7800)

- ø30 6306 2RS C3 deep groove ball bearing (Dynamic load rating of 28100 N and a static load rating of 14600)

- Sealed and factory greased for life. Lubricant used LGMT 2.

5. Steel Circlip

- Circlip positioned axially to provide 0.7 mm end play maximum. To SABS SANS1313-1 specifications.

6. Labyrinth Seal

- ø25 5-part nylon labyrinth seal; providing ±65 mm of travel to drastically lower dust and moisture ingress into the idler. Factory greased for life. ø30 makes use of a 3-part labyrinth seal.

7. Flinger Ring/Dust Cover

- Polyethylene dust cover to limit dust and dirt contact between the outside environment and the labyrinth seal.

8. Impact Rubber

- Available in ø133 S25 and S30, ø152 S25 and S30 and ø159 (series 30 only) outside diameter configurations. Natural/Synthetic rubber blended impact rings with a shore hardness between 50-60.

| Throughing | S25 & S30 IDLER. |

| Throughing Impact | S25 & S30 IDLER. |

| Flat Return | S25 & S30 IDLER. |

| V-Return | S25 & S30 IDLER. |

| Throughing Training | S25 IDLER. |

| Flat Return Training | S25 IDLER. |

| Conveyor Frames | IDLER. |